|

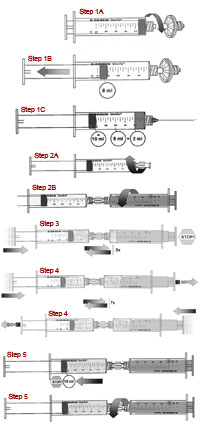

Fig. 8.8a–d. Materials for foam

generation. a Injekt syringe with

Luer-Lock 10 ml for foam

generation,b Combidyn adapter,

f/f, for the safe connection of the

syringes during foam generation,

c Omnifix syringe with Luer-

Lock 10 ml, for foam generation,

d Sterifix 0.2 -µm sterile filter

(Personal communication from

J-C.G.R. Wollmann M.D.) |

Using the Monfreux method, the outlet of a glass syringe that contains liquid sclerosing solution is sealed by a rubber or plastic cap. Pulling back the piston generates a negative pressure, which draws air into the syringe through the fine gap between the syringe body and the piston. The end result produces a fluid foam with relatively large bubbles. Monfreux foam properties vary with the concentration of the sclerosant, type of syringe, width of the capillary gap between the body of the syringe and the plunger, and the method and duration of pulling back the piston [17]. Therefore, a defined ratio of gas and sclerosant or defined bubble size cannot be determined with this technique [17]. The DSS, a technical variation of the Tessari technique, utilizes two disposable, latex-free, plastic syringes each with a Luer- Lock connection, a 10-ml Injekt syringe, and a 10-ml Omnifix syringe (with a rubber plunger). The Omnifix syringe is fitted with a 0.2-µm filter for sterilization, and exactly 8 ml of air is drawn into the syringe. The filter is removed and 1 ampoule (2 ml) of polidocanol 3% is drawn into the Omnifix syringe. The two syringes are connected to the Combidyn adapter. Back-and-forth pumping movements are performed five times against resistance by exerting thumb pressure against the piston of one of the syringes. The two components should then be well mixed. The foam is further mixed by quickly pumping back-and-forth seven times without resistance. The sclerosant-to-air ratio is fixed at 1:5 (1+4). The half-life is approximately 150 s, and the initial mean bubble size is 70 µm [17]. The DSS procedure produces a small-bubbled, viscous foam [15] (Figs. 8.8 and 8.9).

The Tessari tourbillon technique utilizes two syringes (various sizes have been described), one containing 0.5 ml of Aethoxysklerol solution and the other containing 2–2.5 ml of air. Various concentrations of sclerosant have been used, but 1% and 3% concentrations are primarily used for large and very large vessels, respectively. The outlets of the two syringes are connected to a three-way stopcock. Pumping the contents of the two syringes back and forth 20 times causes a turbulent flow that generates foam [15]. The three-way stopcock can vary the size of the bubbles by changing the size of the passageway. By turning the cock, a narrow passage can generate high turbulence and, consequently, smaller bubbles. Conversely, a wider passage will generate less turbulence and therefore larger bubbles. Regardless of the concentration of the sclerosant, the gas proportion is approximately 0.7–0.83.Tessari’s method yields a very fine, small-bubbled foam, which is fluid if low concentrations of sclerosant are used or viscous if high concentrations are used [15, 18, 19]. The half-life depends on the concentration and the type of syringe used (silicone content).